Main Article Content

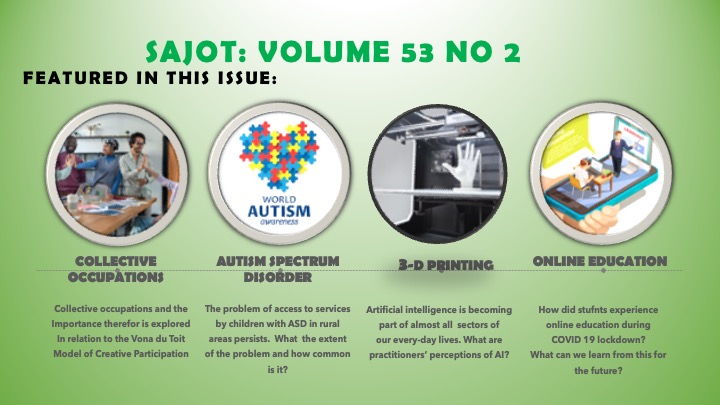

Occupational therapists’ acceptance of 3D printing

Abstract

In occupational therapy, three-dimensional printing is

being explored as an alternative design and manufacturing technique to

the conventional fabrication of orthotics and assistive devices. The global

applications and literature are rapidly growing, but the South African – specific

literature is deficient. The Technology Acceptance Model depicts that one’s

perception of any particular technology is a significant determinant of their

acceptance of it, determining whether the technology system is successfully

adopted or disregarded.

Aim: To determine the perceived acceptance of three-dimensional printing

technology amongst occupational therapists in KwaZulu-Natal and whether

exposure to the technology system, in the form of a three-dimensional printing

workshop, influences their perception of the technology.

Method: The study followed a multi-method design consisting of two phases;

phase one involved the creation of the intervention tool (workshop), which

was developed through a process guided by Design-Based Research. Phase

two involved the implementation of the intervention and data collection.

Therapists documented their perceptions in a questionnaire before and after

exposure; following a pre and post-test design, enabling comparison. The

questionnaires were based on the Technology Acceptance Model, including 13

questions scored on a seven-point Likert scale and five open-ended questions.

The quantitative data were analysed descriptively, and qualitative data were

analysed thematically.

Results: All four categories of the Technology Acceptance Model-based

questionnaire displayed a significant change (p < 0.05) between the pre and

post-test responses, with a medium effect size.

Conclusion: Exposure to three-dimensional printing influences therapists’

perception of the technology.

IMPLICATIONS FOR PRACTICE

• The application of Three-Dimensional Printing (3DP) in occupational therapy

practice has the potential to enable increased accuracy and precision of

items fabricated by therapists; enabling customisation and individualisation

to the exact specifications of a patient.

• 3DP can open doors to a broad spectrum of items that are not easily

accessible, affordable, or not even available, accessing ideas and blueprints

from a global pool of resources through open-source sites.

• With the process of fabrication being digital, not only does this reduce

manual labour, but fabricating without touching the patient can reduce

pain and prevent disruption of a repair/ surgical site/ wound.

• The digital process also allows patients to see and visualise the product

during the design process, enabling input prior to printing, contributing

to reduced wastage.